| |

| |

|

|

|

|

|

|

|

|

| |

|

|

| |

|

|

| |

Vision Engineering |

|

|

|

|

| |

|

|

| |

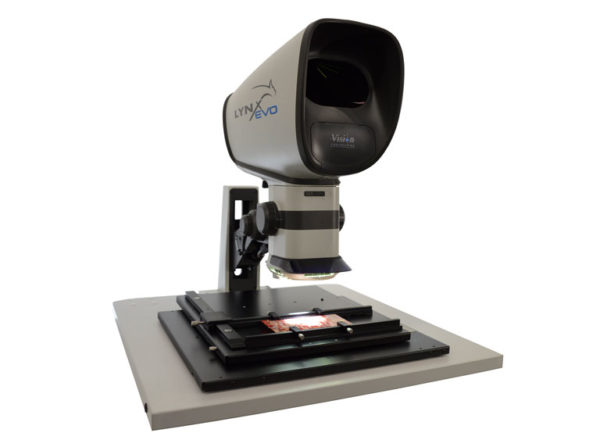

Respected by scientists, engineers and technicians across the globe, Vision

Engineering Ltd is a true British success story. From our foundation in 1958, we have

grown to become the world's leading ergonomic microscopy company, designing and

manufacturing high quality microscopes, digital instruments, and inspection and

non-contact measuring systems.

Today, over 90% of our products are exported around the world. Our success comes from

a culture of innovation, quality and ergonomic design.

|

|

| |

|

|

|

|

|

| |

|

|

|

Fast. Accurate. Comfortable.

|

|

| |

|

|

| |

A favorite in the automotive, aerospace, medical,

mechatronics and telecommunication

industries, our eyepiece-less stereo microscopes and high performance

digital

microscopes let you examine anything from the smallest SMT component to the

largest

printed circuit board (PCB) quickly, more accurately and in far greater comfort.

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

Goods in

|

|

| |

|

|

| |

|

|

Goods in and inbound quality control tasks are

transformed with Vision Engineering's

ergonomic microscopes. Integrated circuits, ball grid arrays, dual flat no-lead,

quad

flat no-lead, unmounted components and bare PCBs can all be examined in moments.

|

|

|

| |

|

|

|

|

|

| |

|

|

|

Never miss a thing

|

|

| |

|

|

| |

Checking the quality of plating on PCB through holes or

looking around and even under

the leads (gull wings) of a Quad Flat Package (QFP) is made easier with the

360°

viewer

on Lynx EVO

and EVO Cam

II. The 34°

degree oblique view, which rotates

360°,

around the

center, allows quick visual inspection around the sides of a through hole or

around each

lead. Inspecting for solder quality, bridging, pad lifting, and other hidden

defects is

possible without the need for difficult manipulations of the board.

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

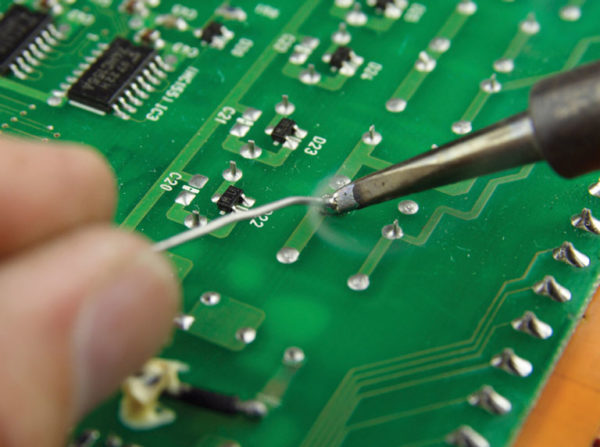

Prototyping, hand assembly and rework

|

|

| |

|

|

| |

|

|

Hand assembly tasks benefit from an insight to the 3D nature of a subject - and

the

position of tools in that space - for easier hand-eye co-ordination and greater

accuracy. The unique 3D views of Lynx EVO, DRV-Z1 and Mantis improve accuracy and

reduce

operator fatigue, improving productivity and throughput.

|

|

|

| |

|

|

|

|

|

| |

|

|

|

Production and quality control

|

|

| |

|

|

| |

Visual inspection of defects including misaligned,

wrong or missing components, solder

defects, poor wetting, pad lifting, and fillet tearing can be effortlessly

achieved with

our 2D camera-based and 3D stereo systems. 3D systems offer the additional benefit

of

revealing surface finish and textures which can indicate poor soldering quality

and

other defects. For the most critical PCBAs, 3D visual inspection using Vision

Engineering's EVOTIS is ideal. With the ability to hold PCBAs safely, its XY

locking

stage ensures each termination can be visually inspected thoroughly.

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

Finishing / Coating

|

|

| |

|

|

| |

|

|

Choose a Vision Engineering solution with UV illumination to reveal defects in

coatings.

Common coating defects such as contamination, thinning, over application and poor

adhesion all become clear and easy to see.

|

|

|

| |

|

|

|

|

|

| |

|

|

|

Reporting

|

|

| |

|

|

| |

Creating detailed reports, complete with images,

measurements and annotations, is quick

and easy with Vision Engineering's powerful but intuitive software.

|

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

| |

|

|

|

|

|